qzshanying

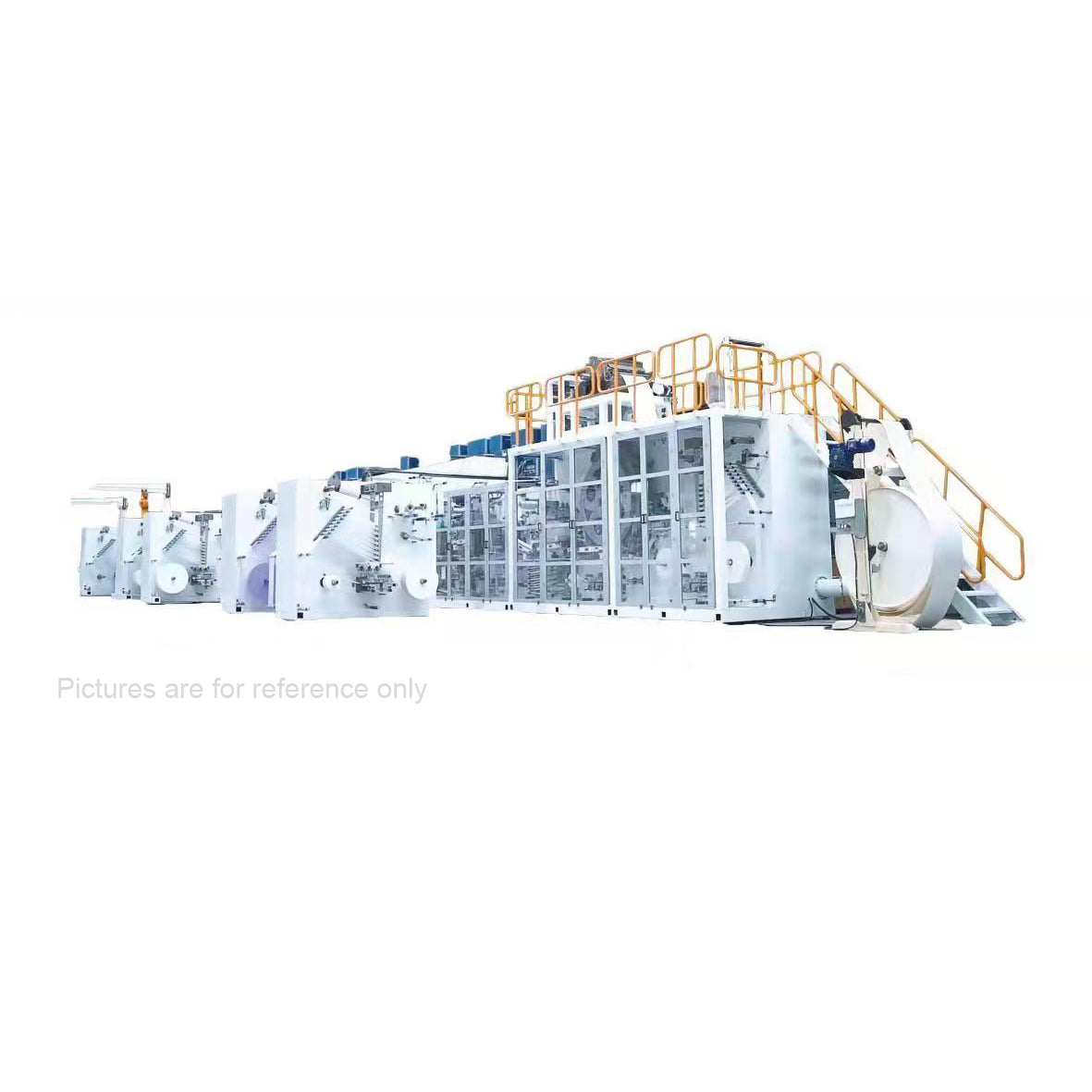

Full Servo 0 Wastage Elastic Ear T shape Baby diaper main machine ( TPM-NK-500-SV )

Full Servo 0 Wastage Elastic Ear T shape Baby diaper main machine ( TPM-NK-500-SV )

|

Origin |

China |

Trademark |

TPM Machinery |

|

Model NO. |

TPM-NK-500-SV |

Min. Order |

1Set |

|

Computerized |

Yes |

Automatic Grade |

Full Servo |

|

Trade Terms |

FOB Xiamen Port |

Delivery Time |

180 days after receive 30% deposit by T/T |

|

Payment Terms |

T/T, |

Packing Way |

Antirust Oil+ PE Film Cover Whole Machine+ Wooden Pallet Packing |

Main Parameter:

|

Performances |

|

||

|

1. Volume (million pieces/ year) |

40-140 million pieces |

||

|

2. Designed Speed |

600pcs/min |

||

|

3. Stable Speed |

500pcs /min (I shape) |

||

|

4. Passing rate |

≥ 97% (Not include the glue applicator, Auto Splicing) |

||

|

Technical Parameter: |

|

||

|

1. Power Installed |

400KW |

||

|

2. Power Used |

220KW |

||

|

3. Electric wire |

3×120mm2+1×50mm2+1×25mm2 |

||

|

4. Compressed Air Supply |

0.6~0.8Mpa |

||

|

5. Compressed Air Absorption |

4000 Nl/min |

||

|

6. Machine Size |

35.0m× 2.30m× 3.5m(L× W× H ) |

||

|

7. Working Size |

39m× 9.0 ´5.0m (L× W× H ) |

||

|

8. Machine Weight |

about 50t (whole production line) |

||

|

9. Machine Color |

confirm with customer |

||

|

10. Machine Direction |

From Right to Left (can be designed as customer’s demand) |

||

|

11. Finish Product Size XL、L、M、S ( Based on Customer’s requirement) |

|

Max |

Min |

|

Length |

550mm |

350mm |

|

|

Width |

350mm |

200mm |

|

Baby diaper manufacturing machine: ingenious technology, caring for the future

In the field of infant care, baby diaper manufacturing machines have become a model of modern manufacturing with their excellent performance and precision craftsmanship. It is not only a machine, but also a full commitment to the health and comfort of babies, providing safe, soft and efficient diaper products for families around the world.

Core advantages

1. Fully automated and efficient production

The baby diaper manufacturing machine adopts a fully automated production line, from raw material processing to finished product packaging, with intelligent operation throughout the process, greatly improving production efficiency and ensuring the high quality and consistency of products.

2. Precision technology, ultimate care

Through high-precision molds and intelligent control systems, the machine can create ultra-thin, soft, and highly absorbent diapers that fit the baby's delicate skin perfectly and provide a comfortable experience all day long.

3. Safe and environmentally friendly, a safe choice

The machine uses environmentally friendly materials and clean production technology to ensure that the product is safe and harmless, while reducing resource waste and carbon emissions, contributing to sustainable development.

4. Flexible customization to meet diverse needs

Support customized production of various specifications, materials and functions to meet the diverse needs of different markets for baby diapers, and help brand innovation and differentiated competition.

Innovative technology drives the future of the industry

The baby diaper manufacturing machine integrates the cutting-edge technologies of mechanical engineering, automatic control and material science, which not only improves production efficiency, but also promotes the industry to develop in the direction of intelligence and greenness.

Protect baby health and convey love and care

Behind every diaper is the crystallization of technology and craftsmanship. With its excellent performance and reliable quality, the baby diaper manufacturing machine provides intimate health protection for babies around the world, allowing every baby to grow happily in comfort and safety.

The baby diaper manufacturing machine is not only a production equipment, but also a solid backing for the infant care industry. Choosing it means choosing quality, innovation and responsibility. Let us join hands and use the power of technology to escort baby health and protect the hope of the future!